Utilize a heat transfer method to affix logos or personal messages onto your sphere. This process involves using a specialized transfer paper that adheres through heat and pressure, allowing for vibrant, durable designs that withstand wear on the course.

For those seeking a more precise finish, consider pad printing. This technique employs a silicone pad to apply ink directly onto the surface of the sphere, ensuring that intricate designs and fine details are captured. Select high-quality inks specifically formulated for use on synthetic materials to prolong the lifespan of your text.

Another option is direct-to-substrate printing, which involves specialized printers that can print directly onto the sphere’s surface. This technology offers versatility in design and allows for full-color images, enhancing the visual appeal of your customized piece considerably.

No matter the method chosen, it’s crucial to ensure that the surface is clean and free from contaminants. This preparation step significantly influences the adhesion and clarity of the final design, resulting in a product that both looks professional and lasts longer under various playing conditions.

Techniques for Customizing Sphere Surfaces

Utilize pad printing for detailed designs on rounded surfaces. This method transfers ink from a silicone pad onto the sphere, accommodating various complexities in artwork. Ensure the chosen ink is suitable for non-porous materials to achieve longevity.

Ultrasonic welding is effective for embedding personalized identifiers. This approach melds design elements into the exterior, making them resistant to wear and tear, ideal for frequent use and outdoor environments.

Recommended Inks for Best Results

| Ink Type | Features |

|---|---|

| UV-Cured Inks | Quick drying, durable, resistant to fading |

| Solvent-Based Inks | Excellent adhesion, suitable for various surfaces, weather-resistant |

| Water-Based Inks | Eco-friendly, safe, less odorous |

Preparation for Application

Clean the surface thoroughly to remove any residues. A light abrasive can enhance adhesion, but avoid deep scratches that might affect structure. Proper alignment during application ensures accurate placement of the design.

Allow adequate drying time post-application to enhance durability and protect the design from premature damage or smudging. Adjust the drying conditions based on the ink type used for optimal results.

Selecting the Right Printing Method for Golf Balls

Laser engraving offers precision and durability, making it an ideal choice for intricate designs. This technique ensures that the artwork remains intact regardless of wear and tear during gameplay.

Pad Printing

Pad printing provides versatility and is suitable for various designs and colors. It effectively transfers ink to the textured surface of the sphere, yielding clear and vibrant outcomes. Ideal for promotional items, this method can accommodate large print runs efficiently.

Screen Printing

Screen printing is optimal for bold graphics and large-scale designs. This approach involves creating a stencil and applying layers of ink, allowing for bright colors and solid coverage. While it may not be as detailed as other methods, it is cost-effective for high-volume jobs.

Preparing Surfaces for Customization: Cleaning and Smoothing

The first step involves meticulous cleaning of the spheres to eliminate any debris or residues. Utilize a soft cloth and a gentle detergent, ensuring that each item is thoroughly scrubbed before rinsing with clean water. This process guarantees proper adhesion and a flawless finish.

Next, inspect each piece for imperfections. Small blemishes can interfere with the application of designs. For those that require smoothing, utilize fine-grit sandpaper or a specialized polishing tool. Lightly buff the surface until it achieves a smooth texture. This careful treatment enhances overall quality and ensures that the subsequent application will be successful.

Additional Preparation Techniques

In cases where the material has a glossy finish, consider applying a primer specifically designed for the material composition. This step not only promotes better ink absorption but also fortifies the durability of the designs.

A final wipe with an alcohol-based solution can remove any lingering oils, preparing the surface for the next steps in the customization process. This method guarantees a professional outcome that stands the test of time.

Choosing the Best Ink and Equipment for Golf Ball Printing

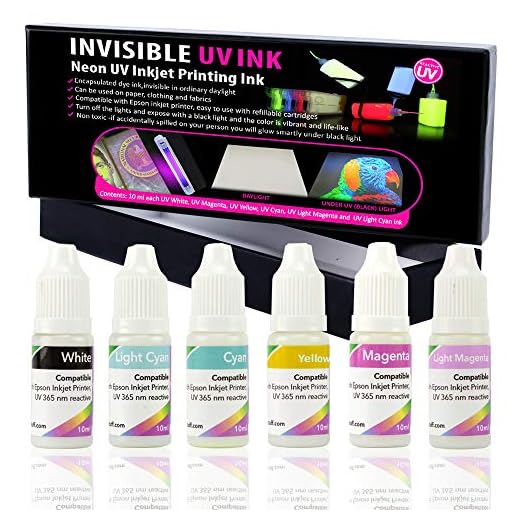

Select UV-cured inks specifically designed for synthetic surfaces. These inks adhere well to the dimpled texture and provide durability against weather conditions. Look for options that offer vibrant colors and excellent UV resistance to ensure long-lasting results.

Recommended Printing Equipment

Invest in a high-quality direct-to-object (DTO) printer with a flatbed option. This type allows for precise placement on spherical objects, accommodating the unique shape of spheres. Consider models with adjustable height settings to accommodate various ball sizes efficiently.

Additional Tools and Supplies

Utilize a heat gun or a drying station to set the ink post-application. A lint-free cloth is essential for surface preparation, while a cleaning solution formulated for plastics guarantees optimal adhesion. Make hand-rollers available for even ink distribution during the setup process.

Setting Up a Printing Station for Golf Balls

Design a dedicated workspace with adequate lighting and ventilation to ensure high-quality results. This area should be free from dust and contaminants to maintain the integrity of your images.

Necessary Equipment

- Printing machine designed for spherical objects.

- Drying station for immediate handling post-application.

- Cleaning tools (lint-free cloths, solvents).

- Measurement tools for precision alignment.

Workspace Arrangement

Arrange equipment in a logical flow: start with cleaning, move to printing, and then to drying. Ensure that each station is accessible to minimize movement and improve efficiency.

Provide storage for ink and other supplies close to the workstation. Label cabinets and drawers to maintain order and quick access.

Safety Precautions

- Use gloves to handle materials and avoid skin contact with chemicals.

- Wear masks if working with solvents to prevent inhalation of fumes.

- Keep a fire extinguisher nearby in case of emergencies.

By implementing these guidelines, you can create an organized and effective environment for producing customized designs on spherical surfaces, ensuring repeatable and professional outcomes.

Printing Designs: Techniques for Precision and Quality

Utilizing screen printing is highly recommended for achieving accurate designs on the surface of spheres. This technique allows for consistent layering of ink, essential for complex graphics and logos.

Pad printing offers another effective option. It transfers ink from a silicone pad onto the object, accommodating uneven surfaces effectively. This method excels in detailing, making it ideal for intricate designs.

For high-resolution images, consider using UV printing. This technology cures the ink immediately with ultraviolet light, forming a durable layer that withstands wear and tear while maintaining vibrant colors.

Laser engraving presents a unique approach for permanent markings. It removes a thin layer of material, providing a distinct finish that adds texture and longevity to the design.

Consistency in design application is crucial. Conduct test prints on dummy items to verify color accuracy and positioning before executing the final run.

Utilize specialized software for design creation. Vector-based graphics preserve clarity and quality when scaled, ensuring optimal results regardless of the chosen method.

Maintain precise control over the printing environment. Monitor temperature and humidity levels to prevent ink drying issues and ensure optimal adhesion on the surface.

Regular maintenance of equipment ensures high-quality output. Clean the printing plates and pads regularly to avoid cross-contamination and preserve the integrity of colors.

Post-Printing Care: Curing and Storing Printed Golf Balls

Allow the designs to cure adequately. Use a UV light for at least 30 minutes if UV ink is applied; otherwise, let the items sit for 24 hours in a controlled environment. This step is crucial for ensuring durability and adherence of the ink.

Store the items in a cool, dry place away from direct sunlight. A temperature between 60°F and 75°F is ideal. Avoid humid conditions, which can compromise the integrity of the prints.

Handling and Inspection

Handle printed pieces with care to avoid smudging or scratching. Inspect each item for consistency in quality. Any defect should be noted and addressed immediately to prevent further issues in future production runs.

Packaging Considerations

Utilize soft packaging materials to protect the surfaces during transportation. Consider individual boxes or padded envelopes to avoid friction. Label groupings clearly for easy identification and to maintain stock organization.

Regularly monitor stored items to ensure no environmental factors are adversely affecting them. Proper management will extend the lifespan of the printed designs and help maintain customer satisfaction.

FAQ:

What are the best methods to print on golf balls?

There are a few popular methods for printing on golf balls, including pad printing, screen printing, and laser engraving. Pad printing is commonly used for logos and text because it can produce high-quality images on curved surfaces. Screen printing allows for vibrant colors and is ideal for larger designs. Laser engraving offers precision and durability, making it suitable for personalizing golf balls with names or initials. Each method has its advantages depending on the desired outcome and budget.

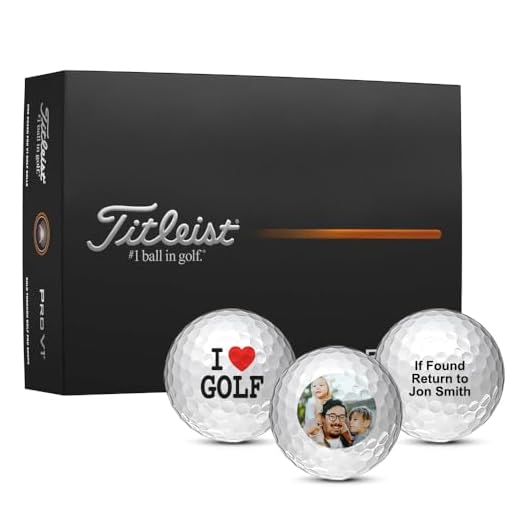

Can I customize golf balls at home, and if so, how?

Yes, you can customize golf balls at home using a few different techniques. One popular method is using stickers or decals specifically designed for golf balls, as these can easily adhere to the surface without affecting playability. You might also consider using a specially formulated paint or markers to create your designs; however, ensure these products are suitable for golfing equipment. Always test a small section first to check for durability and visibility. While home customization offers a personal touch, it’s essential to remember that professional printing methods usually yield better durability and aesthetic quality.