Utilize a high-quality tubing cutter specifically designed for fibrous materials. This tool ensures a clean and precise finish, reducing the chance of splintering. Securely clamp the stick in a stable position to maintain control during the process.

Mark the desired length clearly with a fine-tip marker. Measure twice to confirm accuracy; this eliminates the need for rework and enhances satisfaction with the final result. Gently rotate the cutter around the marked area, applying slight pressure until the material is severed.

After the cut is complete, smooth any rough edges using fine sandpaper or a file. This step prevents damage during reinstallation and enhances the overall aesthetic. When reassembling, ensure that all components fit snugly for optimized performance on the course.

Instructions for Modifying Your Equipment

Utilize a precision cutting tool, such as a fine-toothed saw or a specialized cutter designed for composite materials. Ensure the blade is sharp to minimize fraying at the edges.

Prior to performing any alterations, measure the desired length carefully using a measuring tape. Mark the blade position using a marker or tape to ensure accuracy.

Protective Measures

Wear safety goggles to shield your eyes from debris. Consider using a dust mask to avoid inhaling particles generated during the cutting process. Secure the component in a vice or clamp to prevent movement while working.

Finishing Touches

After completing the modification, sand the cut end gently with fine-grit sandpaper to achieve a smooth finish. Check for any sharp edges that may cause discomfort during use. Clean the area thoroughly before reassembling any parts.

Selecting the Right Tools for the Job

Utilize a high-quality fine-toothed saw for precision. A junior hacksaw or an alternative with at least 32 teeth per inch will deliver clean, controlled results. Invest in a sturdy vice or clamp to secure the item firmly during the process.

Measuring Instruments

A reliable measuring tape is essential. An alternative such as calipers ensures accuracy for precise adjustments. Mark cutting points with a non-permanent marker or masking tape to maintain visibility without leaving residue.

Finishing Tools

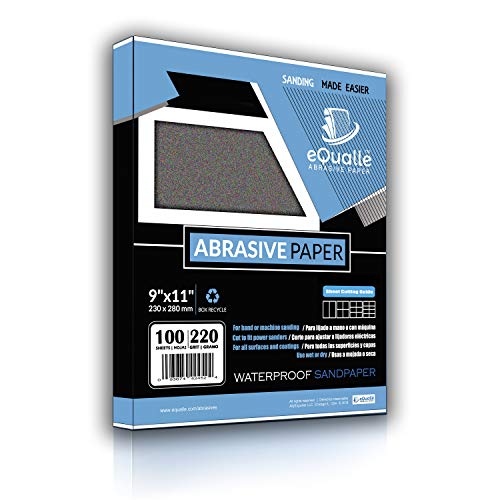

After the primary task, smooth edges are paramount. Employ sandpaper with varying grit levels–starting from 80 to 220–for a refined finish. A specialized reamer can be invaluable for addressing any rough edges, ensuring a seamless transition.

Finally, safety gear like goggles and gloves is non-negotiable to protect from debris and potential injuries. Prioritize quality over quantity when selecting tools for this undertaking to achieve the best outcomes.

Measuring the Desired Shaft Length Accurately

For precise adjustment, follow these steps to measure the optimal length of the rod:

- Gather Tools: Prepare a measuring tape, a marker, and a level surface.

- Determine Fitting Position: Stand upright in a relaxed posture, holding the item at address position.

- Measure from Ground to Grip: Measure from the floor to the grip area’s bottom, ensuring the item is positioned correctly.

- Note Desired Length: If standard lengths do not suit preferences, customize based on individual height and swing style.

- Double-Check Measurements: Repeat the measurement, ensuring accuracy. Small errors can lead to significant differences in performance.

Once the optimal length is established, mark it clearly with your chosen method for the next steps of the customization process. Accurate measurement leads to better handling and efficiency.

Marking the Cutting Point Clearly

Use a fine-tip permanent marker or tape measure to mark the location where you want to shorten the rod. Ensure the mark is highly visible from various angles, as this will simplify the process. A straight edge can assist in drawing a precise line if you’re using a marker.

Double-Check Measurements

Before finalizing your marking, verify your measurements one last time. It’s beneficial to also mark a second reference point further down the length to ensure alignment during the trimming process. Having two points can help in maintaining a consistent angle while performing the task.

Consider Using a Straightedge

Employing a straightedge or a ruler during marking provides greater accuracy. Align the straightedge so that it runs parallel to the desired cut, and mark along its edge. This method eliminates the potential for slippage and guarantees a uniform marking for a cleaner outcome.

Cutting Techniques for a Clean Finish

Using a fine-toothed saw will yield the best results; it minimizes fraying and ensures a smooth edge. Maintain a steady hand and apply consistent pressure throughout the process.

Using a Dremel Tool

A Dremel tool equipped with a cutting wheel provides precision. Ensure the tool is set to a moderate speed to prevent overheating, which can damage the material. Move slowly and allow the cutting wheel to do the work, reducing the risk of splintering.

Sandpaper or File Finishing

After trimming, use fine-grit sandpaper or a file to smooth any rough edges. Wrap the sandpaper around a small block to keep an even surface and achieve a polished finish. Emphasize the importance of checking frequently to avoid over-sanding.

Cleaning the area around the cut is equally important. Remove dust and particles immediately, as they can interfere with reassembly and performance.

Preparing the Shaft After Cutting

Once the length adjustment is made, it’s crucial to ensure the end of the rod is properly finished for optimal performance and durability.

Smoothing the Edges

Use a fine-grit sandpaper or a specialized file to carefully smooth the cut edge. This step prevents any sharp fragments from causing injury or damaging other components during assembly.

Applying Epoxy and Reinforcement

For securing the tip of the rod, apply a high-quality epoxy adhesive that is specifically designed for graphite materials. Ensure an even coat is spread on the interior of the connector piece before joining. For added strength, consider wrapping a layer of fiberglass tape around the joint area, allowing it to cure firmly.

Once everything is assembled, leave it to cure in a controlled environment, ensuring that temperature and humidity levels are stable for optimal adhesion.

Reinstalling the Grip on Your Cut Shaft

Prepare the new grip by applying a suitable amount of double-sided tape around the top end of the modified stick. Ensure the tape is evenly distributed, as this provides a secure hold and prevents the grip from slipping during play.

Next, utilize a grip solvent to facilitate easy installation. This solvent allows the grip to slide into place without excessive force. Apply the solvent generously to the inner surface of the grip and the tape on the shaft.

Installation Steps

Align the grip with the desired orientation relative to the clubhead, ensuring it matches your preferred positioning. Slide the grip onto the shaft, pushing firmly but smoothly. If the grip encounters resistance, use more solvent instead of forcing it. Aim for a snug fit without twisting.

Finalizing the Grip

Once the grip is in place, give it a gentle twist to ensure a secure bond with the tape underneath. Leave the grip to set for a few hours, allowing the adhesive properties of the tape to activate fully. It’s advisable to wait at least 24 hours before using the equipment to ensure everything is securely fixed.

| Tool/Material | Purpose |

|---|---|

| Double-sided tape | Secures the grip to the modified stick |

| Grip solvent | Facilitates smooth installation |

| New grip | Provides the necessary feel and control |

FAQ:

What tools do I need to cut a graphite golf club shaft?

To cut a graphite golf club shaft, you will need a few essential tools. The main tools are a shaft cutting tool or a hacksaw specifically for graphite, a measuring tape or ruler, and a marker for marking the cut line. Additionally, using a clamp to secure the shaft while cutting will help ensure accuracy and safety. A filing tool or sandpaper can also be useful for smoothing the edges after the cut is made.

How do I measure the correct length for cutting a graphite golf club shaft?

Measuring the correct length for cutting a graphite golf club shaft is crucial for maintaining performance. First, determine the desired length based on your height and swing style. Use a measuring tape to measure from the end of the grip to the desired length. Mark this point clearly with a marker. It’s a good idea to double-check your measurements to avoid cutting too short. If you have a reference club that feels comfortable, you can also use it as a guide for your measurements.

What precautions should I take when cutting a graphite golf club shaft?

When cutting a graphite golf club shaft, it is important to take several safety precautions. First, wear protective eyewear to shield your eyes from graphite dust and potential flying particles. Make sure to work in a well-ventilated area to avoid inhaling any dust created during the cutting process. Secure the shaft tightly in a clamp to prevent any movement while cutting, which can lead to a jagged edge or an inaccurate cut. After cutting, smooth the edges with a file or sandpaper to prevent damage to grips and hands when reassembling the club. Lastly, ensure you are using the right cutting tool specifically designed for graphite, as other tools can cause damage to the shaft.